Setup-Guide: Pulsed Photothermal Reflectance

+thermal conductivity +thermal boundary resistance +thermal transport Nanosecond laser +CW laser +photodetector

Author:

Majid Kabiri Samani (PhD NTU 2014)

At a glance: • Knowledge article • Method •Setup

Pulsed Photothermal Reflectance is an optical and noncontact measurement technique that commonly used to measure the thermal conductivity and thermal diffusivity of thin film and bulk materials. This technique can measure thermal boundary resistance between the layers in multiyear thin-film structures as well. Pulsed photothermal reflectance is a pump-probe technique for the temperature measurement in nanosecond and microsecond regime to test heat dissipation in semiconductor devices. This application note will discuss the application of pulsed photothermal reflectance, experimental setup and necessary components in detail.

Contents

Application

Pulsed Photothermal Reflectance technique is simple, noncontact, and requires little sample preparation. Some of the capability of this technique are listed below:

· Temperature measurement in nanosecond and microsecond regime to test heat dissipation in semiconductor devices.

· Thermal conductivity measurement of solids materials (bulk) at different temperatures.

· Thermal conductivity measurement of thin films with a minimum thickness of 5 nm at different temperatures.

· Thermal boundary resistance measurement between multi-layers samples at different temperatures.

· Thermal transport investigation in Liquid samples such as coolants for thermal management in electronics systems.

Experimental Setup

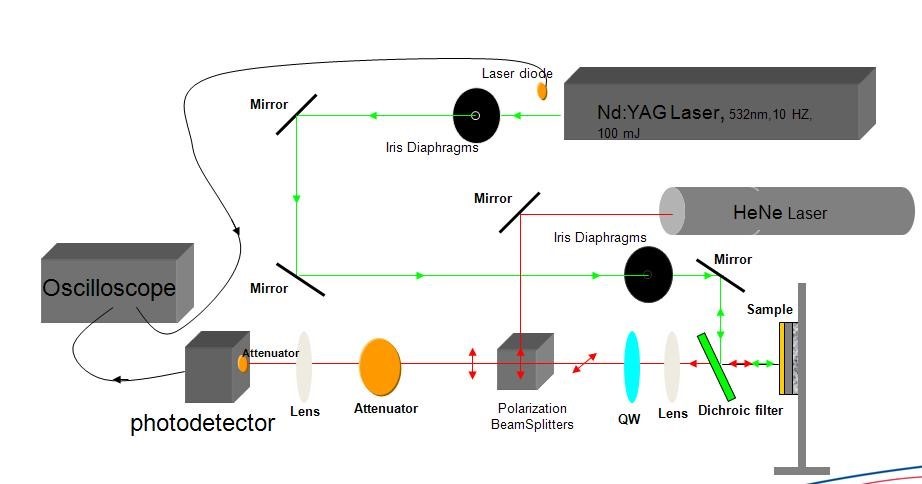

In this technique, a nanosecond laser is used as a pump beam and a CW laser as a probe beam. Nanosecond laser induces the sample surface temperature change over time while a CW laser is applied as a probe to monitor the intensity of the reflected beam from the metalized sample surface. First, the nanosecond laser hits the surface of the sample. The sample’s surface temperature rises sharply and then relaxes in time. It gives rise to a temperature excursion profile that depends on the thermal properties of the underlying films and the thermal resistance between layers. The surface temperature change of the sample induces a change in the refractive index of the surface. The probe beam, which is a CW laser, is then focused at the centre of the pump spot to monitor the changes in the light reflection from the sample surface. Since the temperature and the reflectivity of gold are inversely related, the temperature excursion profile can be obtained by inverting the obtained signal. By solving the heat diffusion equation analytically, the thermal properties of the sample can be extracted from its thermal response captured by the Pulsed Photothermal Reflectance technique.

The figure shows the schematic diagram of the experimental setup. This technique uses two laser beams as a pump and a probe.

Figure 1: Schematic diagram of the pulsed photothermal reflectance technique. In this approach, thermal conductivity of the sample is characterized in nanosecond regime by thermo reflactance technique.

Editor’s Notebook

Recommended Components

Laser

For achieving time resolution in the microsecond region, you may use a nanosecond second laser with a low repetition rate. We suggest Nd: YAG (532 nm) laser pulse with a full width at half maximum of 7 ns, the pulse repetition rate of 10 Hz, and a pulse energy of 5 mJ. For higher time resolution in the picosecond region, you may need to choose a picosecond laser and a sampling microscope for data collection. For probe, our suggestion is one mW He-Ne laser (632.8 nm). You also need to purchase optical components such as polarization beams splitter, dichromic filter, lens, mirror and a silicon photodiode.

Pulse Laser (NIR Picosecond Lasers (QLD-301))

SIMTRUM offers compact and affordable picosecond laser system suitable for TCSPC. The QLD-301 which is a direct-pulsed diode laser system featuring adjustable pulse width, low time jitter, high extinction ratio and high repetition frequency. Laser pulses can be triggered internally or externally with built in precision delay control. For more detail’s specification refer to product page.

Technical tips

Before the measurement, a metal film, preferably gold, is deposited on top of each sample surface to enhance heat absorption. Temperature excursion profile depends on the thermal properties of the underlying layers and thermal resistance between the layers. Because the effective thermal diffusion length on the gold surface is much smaller than the spot size of the pump beam, the measurement can be completed before any significant lateral heat diffusion occurs. Therefore, the heat conduction problem can be modelled as one-dimension vertical heat diffusion in the three-layer (Au/film/substrate) structure.

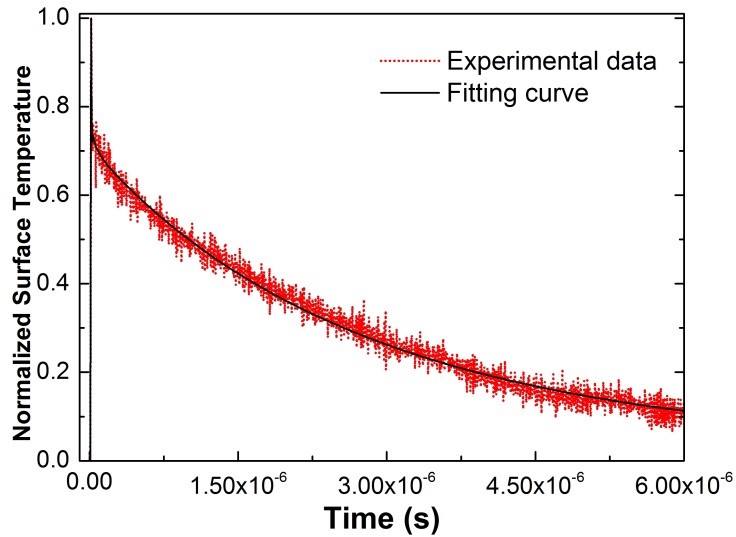

By solving the heat diffusion equation analytically, the thermal properties of a film can be extracted from its thermal response captured by the pulsed photothermal reflectance technique. For a multilayer sample, for example, n-layer, we need to solve n differential equations with 2n coefficients. Computation of 2n coefficient using the Laplace transform technique in the frequency domain is complicated. By using the transmission line theory, the frequency domain solution for a multilayer sample can be obtained. Then, the inverse Laplace transform can be used to get the time-domain solution. Figure 2 shows the transient surface temperature for Au/1 µm SiO2/Si substrate, which obtained from the experimental setup.

Figure 2: Transient surface temperature for Au/1 µm SiO2/Si substrate.

SIMTRUM is active in the Photonics field and welcomes any emails for discussions, questions or implementation. We are based in Singapore (+8GMT) and available via Phone or Email. We are especially interested in customised solutions not commercially available.

Consultation

With over a combined 12 years of experience in the field, Simtrum’s R&D team has developed tens of spectroscopic setups with unique capabilities that are not available in commercial instruments. Our project team is focused on practical and elegant solutions. Please contact us If you need any enquiries about feomtosecond transient absorption spectroscopy and setting up experiments.

References:

O. W. Kgding et al., Appl. Phys. Lett. 65 (13)

Y. Zhao et al., J. Appl. Phys. 96(4563)